Forty years ago, in 1982, even before the Sprick Comfortable, the first plastic bicycle was launched as a completely new development by Volvo engineers in Sweden. It was called “Itera”, which should mean: to live forever (from Latin iter = the way). At that time, the name said it all, because the ABS plastic could not rust and the labour-saving production was supposed to make the “Itera” a bicycle for the masses. However, as the Swedish bicycle dealers consistently rejected it, it was shipped as a kit in direct sales. Until production ceased in 1985, about 30,000 units were sold.

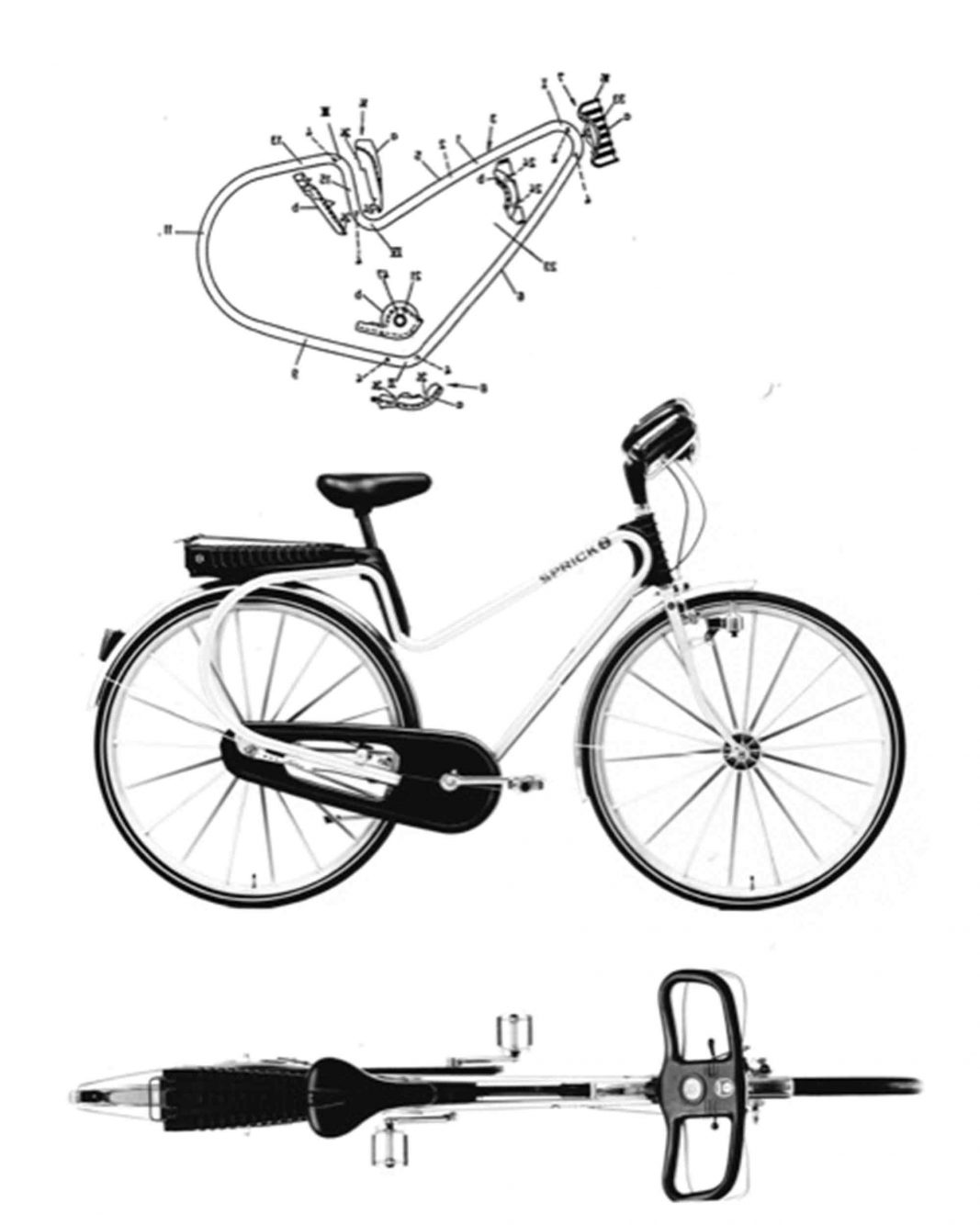

Sprick Comfortable – Overview

The German answer to the Swedish bicycle model Itera: Sprick Comfortable

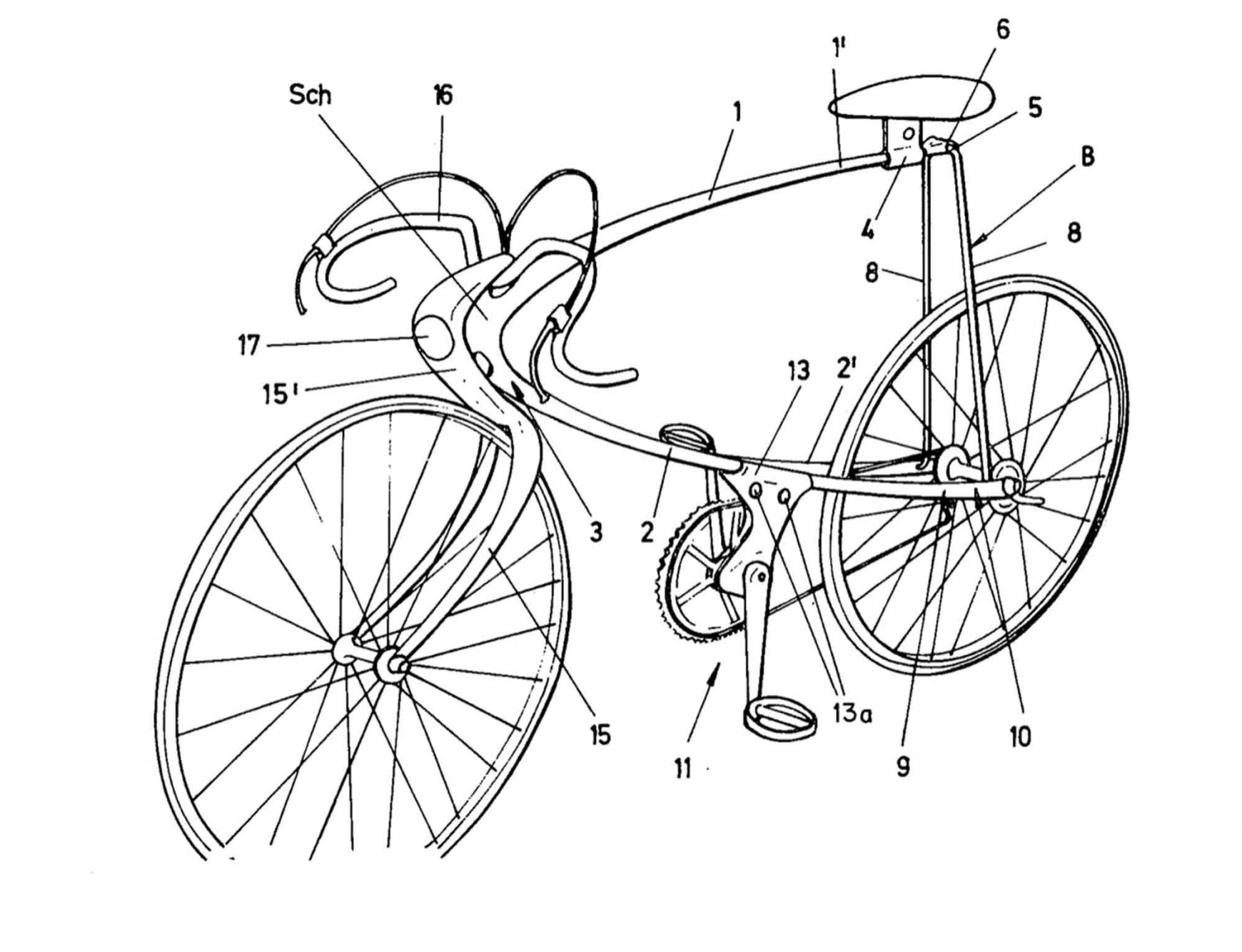

In the German city of Wuppertal, Odo Klose, at the time professor at the former Gesamthochschule, ran his own successful design studio. As early as 1980, he had developed the “Futura” polyester bicycle from a single mould for the Kalkhoff bicycle company, but it probably did not go into production because of the production technology, which was still unusual at the time. He then returned to the classic tubular steel frame and used the plastics only for three large clamps, each of which accommodated the steering shaft, bottom bracket and seat tube.

This replaced the complex socket brazing technique with the simple form closure of the plastic clamps. The vertically flexible double-tube frame offered more suspension than the rigid triangulated diamond frame, also through the use of a tubular steel fork. In comparison, the “Itera”, on the other hand, showed a rather hard ride, also due to its radial pressure spoke wheels made of glass fibre-reinforced polyamide.

Sprick Comfortable: Premiere at the IFMA 1982 in Cologne

In record time, the design was developed to production readiness by Odo Klose in cooperation with Sprick GmbH in Bielefeld and presented as the classic Sprick “Comfortable” city bike at the 1982 IFMA bicycle fair in Cologne. The road bike fans, which included the specialised trade, rejected the comfortable bike just as they had done in Sweden with the “Itera”, so the department stores’ chain Metro, where Sprick was an in-house supplier, took over distribution at a price of 700 D-marks, which seemed too high despite the many extras and was soon lowered to 499 D-marks. Sprick consequently had to react with cheaper components.

Nevertheless, around 20,000 Sprick “Comfortables” were sold within three years. Continental’s futuristic tubeless tyres on the plastic rim without spoke holes were particularly innovative. However, when the tyre punctured on the road, it could not be repaired with a repair kit, but had to be taken to a tyre repair shop. Also innovative was the plastic handlebar with integrated handlebar tube in one piece, reminiscent of the Red Baron’s cockpit. With no pointy brake levers to dig into your stomach in a fall, it was ergonomically and safety-optimised.

Sprick Komfortabel “im Test

At the ICHC 2016 bicycle history conference, Canadian engineer Christopher Morris reported on a self-experiment by alternately riding the “Itera”, the Sprick “Comfortable” and his 20-inch Moulton mini-bike to work, where he also mastered the 7 per cent gradient of the road. On average, he needed 34.5 minutes with the “Itera” (3-speed), 33 minutes with the “Moulton” (2-speed) and 31 minutes with the “Comfortable” (3-speed) – so it could not be due to the effectiveness of the Sprick that it did not have long-term success. In a 1978 interview, Klose remarked about his so-called tension frame: “It flexes and makes riding more comfortable. That’s why the bike is called “Comfortable”. This frame shape did not become popular for bicycles, but it did for buggies.”

The market launch of the Kettler aluminium bicycle in 1978 also had to be carried out in a similar way via the Kaufhof department stores’ chain because of the rejection of the bicycle trade. However, the bicycle dealers finally ordered from Kettler because the customers then increasingly asked for an aluminium bike and the novelty, apart from the welded aluminium frame, was still quite conventional. The fact that Kettler then followed the dealers’ desire for a racing look and developed unnecessary aluminium sleeves is one of the staircase jokes of the two-wheeler industry.